Techtextil vom 23. bis 26. April 2024

Wir sind dabei, auf der internationalen Leitmesse für Technische Textilien und Vliesstoffe. Besuchen Sie uns:

Halle 12.0, Stand D51

Kompetenz³

Wählen Sie Ihren Unternehmensbereich.

Aktuelles von Braunmetall

Techtextil 2024

Vom 23.04. bis 26.04.2024 findet die Techtextil in Frankfurt am Main statt. Die gemet GmbH ist dabei.

Hallenbau-Update

Wir nähern uns Stück für Stück der Fertigstellung der Halle. Mittlerweile ist die Fassade und das Dach kurz vor der Vollendung.

Sponsoring

Wir sind stolz darauf, die E-Jugend des Fußballvereins Graben-Neudorf zu unterstützen!

Jahre am Markt

Angestellte

Länder beliefert

zufriedene Kunden

Stabilität durch Verbundenheit. Innovation durch Freiheit und Vertrauen.

Braunmetall | Imagevideo

Kontakt

Braun Metall Vertriebs GmbH

Ottostr. 16

76676 Graben-Neudorf

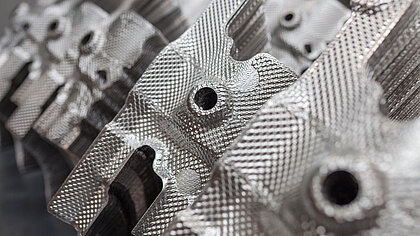

Braun GmbH Folien-Prägetechnik

Ottostr. 16

76676 Graben-Neudorf

gemet GmbH technical adhesive foils

Ottostr. 16

76676 Graben-Neudorf

Warenannahme

Warenannahme: Im Kammerforst 9, 76676 Graben-Neudorf